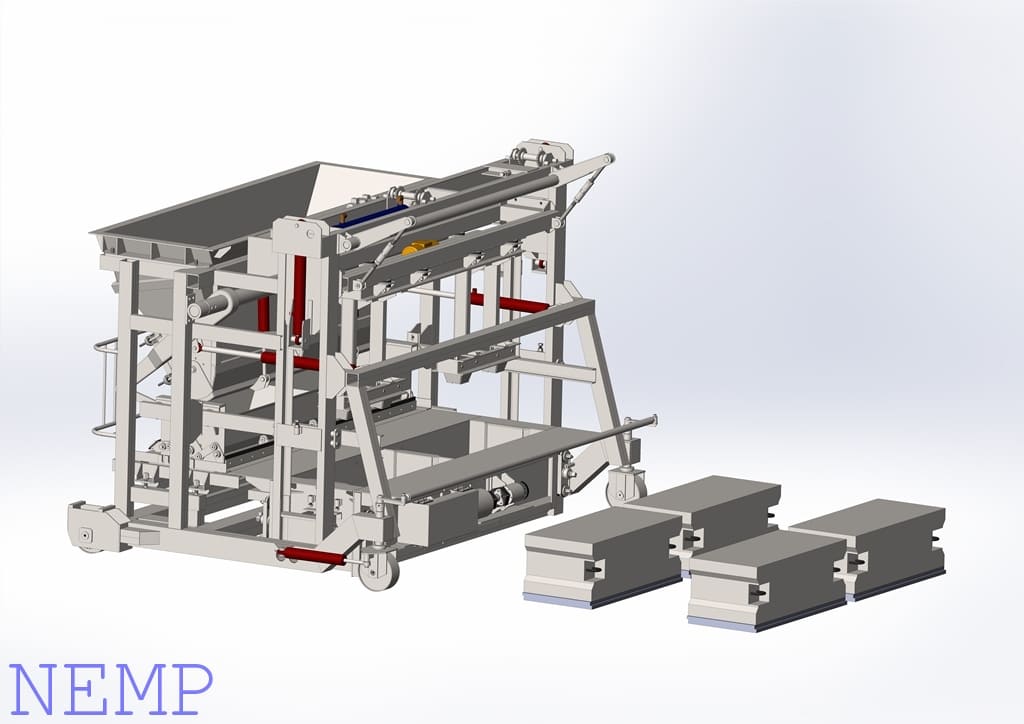

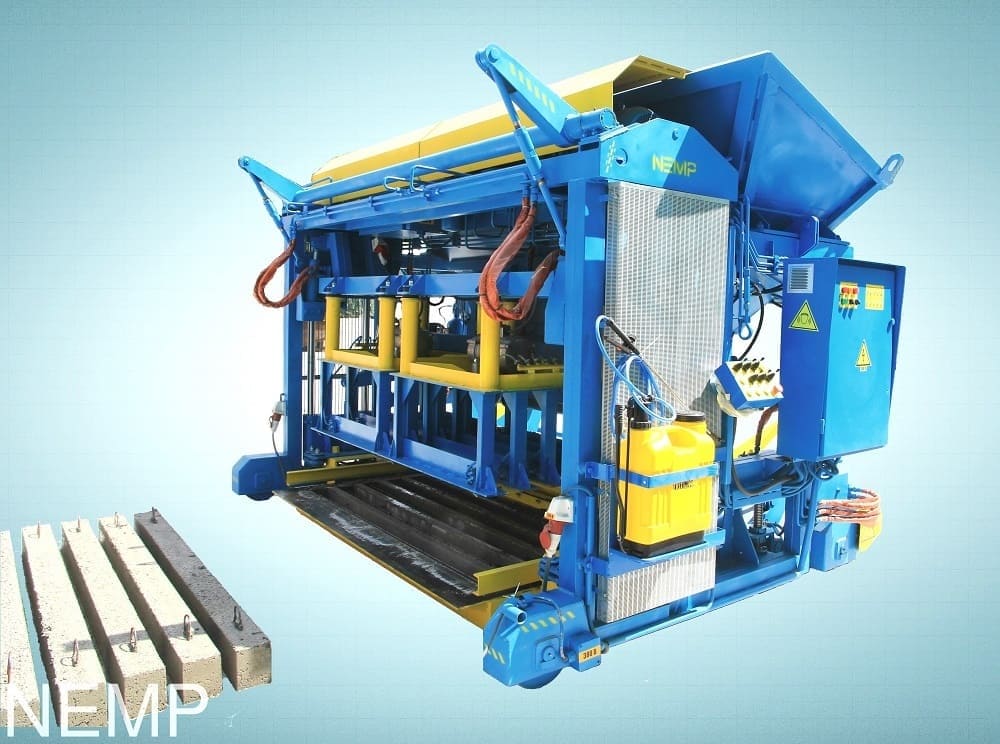

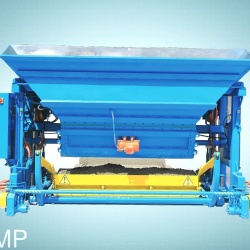

Updated mobile vibropress (model - UPB-SM). Restyled design of 2023. UPB-SM concrete block making machine has been produced for almost 10 years and has the largest geography of deliveries. UPB-SM Restyle is not only a new design, but also the implementation of the hard work of our specialists, the purpose of which was to improve the vibropress at all and improve ergonomic performance. NEMP's Ñoncrete block making machines are a reliable and high-quality construction equipment.

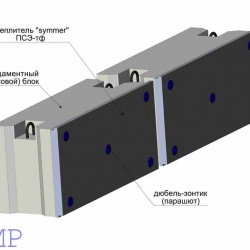

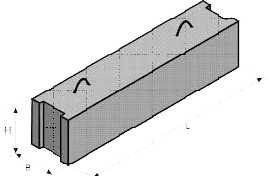

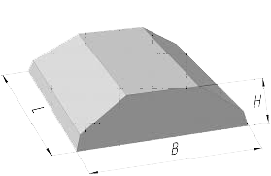

Nomenclature of reinforced concrete blocks:

- 2400*300,400,500,600*580;

- 2400*300,400,500,600*580;

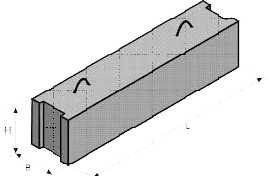

- 1200*300,400,500,600*580;

- 1200*300,400,500,600*580;

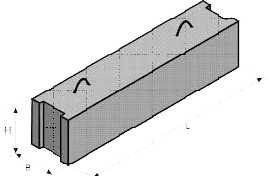

- 900*300,400,500,600*580;

- 900*300,400,500,600*580;

* 600*300,400,500,600*580

* - additional equipment

- 2400*1000,1200,1400,1600*300;

- 2400*1000,1200,1400,1600*300;